In a world where energy costs are constantly rising, and environmental concerns are at the forefront, finding innovative ways to maximize energy efficiency has never been more crucial. Enter heat recovery exchanger—unsung heroes in the battle against wasteful practices. These clever devices capture and repurpose otherwise lost heat, transforming it into a valuable resource that significantly reduces energy bills and carbon footprint. Whether you’re a homeowner looking to enhance comfort or a business striving for sustainability, understanding how these systems work can unlock a new realm of savings and eco-friendly practices.

Introduction to heat-recovery exchangers and their purpose

In a world increasingly focused on sustainability, energy efficiency is a key player in reducing our carbon footprint. Enter heat-recovery exchangers, the unsung heroes of energy conservation. These devices capture and recycle waste heat otherwise lost to the environment. Imagine harnessing warmth from your heating system or industrial processes and using it to power other functions—it’s not just a dream; it’s already happening.

Heat-recovery exchangers are revolutionizing industries’ operations by maximizing energy use while minimizing costs. Whether you’re involved in HVAC systems, manufacturing, or even food processing, understanding these innovative tools can lead to significant benefits for your bottom line and the planet. Let’s explore what makes these systems so essential for modern energy management and explore their transformative potential across various sectors.

The science behind heat-recovery exchangers and how they work

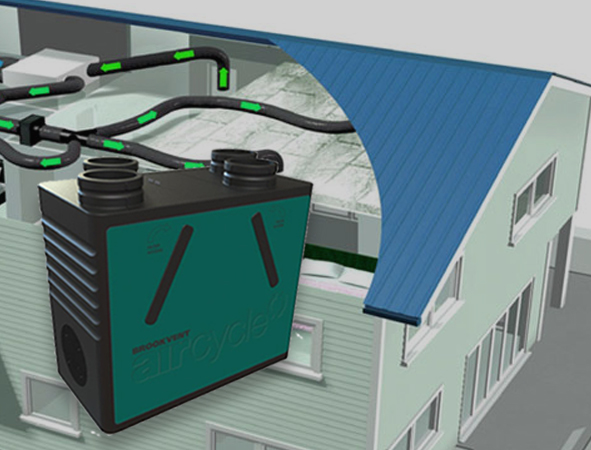

Heat-recovery exchangers are fascinating devices that optimize energy use by transferring heat from one fluid to another. They harness the principle of thermal exchange, allowing warm air or water to transfer its heat before being expelled or sent elsewhere.

These systems typically consist of two separate channels—one for incoming hot fluid and another for cooler receiving fluid. As they pass through the exchanger, heat moves from the warmer stream to the cooler one without mixing.

This process improves efficiency and reduces waste energy, making it a vital component in various applications. By recycling energy that would otherwise be lost, these exchangers contribute significantly to sustainability efforts across industries. The innovative design ensures maximum surface area contact between fluids while maintaining their separation, leading to impressive performance and effectiveness in conserving energy resources.

Benefits of Using an Air Recovery Ventilation System

An air recovery ventilation system is a versatile solution across various industries. HVAC systems enhance indoor air quality while reducing energy consumption. These systems maintain comfortable temperatures with less energy input by recycling heat from exhaust air.

Manufacturing processes also benefit significantly. Many facilities generate excess heat during production. Companies can lower operational costs and improve efficiency by capturing and reusing this energy. Maintaining temperature is crucial for safety and quality in food processing. Heat-recovery exchangers help regulate conditions without wasting valuable resources.

In the pharmaceutical sector, precise climate control is required for sensitive products. These exchangers also play a vital role in minimizing waste and ensuring product integrity. Each industry finds unique advantages in adopting heat-recovery technology. The common thread remains: enhanced sustainability paired with substantial cost reductions creates compelling reasons to integrate them into operations.

Energy Efficiency and Cost Savings Achieved Through the Use of Heat-Recovery Exchangers

Heat-recovery exchangers play a vital role in enhancing energy efficiency across various applications. These devices can significantly reduce the energy needed for heating or cooling by capturing waste heat from industrial processes or HVAC systems.

This means lower utility bills. Businesses can redirect saved funds into other operational areas, driving growth and innovation. Moreover, implementing heat-recovery technology often leads to a quicker return on investment. Due to reduced energy consumption, many organizations experience payback periods of just a few years.

The environmental impact is also noteworthy. Utilizing less energy not only cuts costs but also helps decrease greenhouse gas emissions. Companies increasingly recognise that sustainability and savings go hand in hand with this technology.

In sectors like manufacturing and commercial buildings, the advantages become even more pronounced—transforming wasted resources into valuable assets while promoting greener practices throughout operations.

Types of heat-recovery exchangers

Heat-recovery exchangers come in various types, each tailored to specific applications.

Air-To-Air Exchanger:

Air-to-air exchangers are among the most common. They capture heat from exhaust air and transfer it to incoming fresh air, making this system ideal for HVAC settings.

Water-To-Water Exchanger:

On the other hand, water-to-water exchangers excel in industrial processes. They facilitate heat exchange between two water streams, enhancing thermal efficiency in manufacturing plants or district heating systems.

Plate Heat Exchanger:

Then there are plate heat exchangers, known for their compact design and high performance. They’re often used in food processing or chemical industries with premium space.

Shell-And-Tube Exchanger:

Shell-and-tube models offer versatility across many sectors, including power generation and marine applications. Their robust construction handles high pressures effectively while maximizing energy recovery potential.

Each type plays a crucial role in improving energy efficiency across multiple industries.

Tips for choosing the Best Heat Recovery Ventilation System

Choosing the best heat recovery ventilation system can feel overwhelming, but key factors simplify the process. Start by assessing your specific application—whether for HVAC systems or industrial processes. Consider the temperature and humidity levels you expect to work with. Different exchangers perform better under varying conditions.

Next, look at energy efficiency ratings. Higher efficiency often means lower operational costs over time. Also, account for space constraints in your facility. Some designs are more compact than others.

It’s wise to consult with manufacturers or industry experts who understand your needs deeply. They can provide tailored recommendations that consider both performance and budget.

Lastly, don’t overlook maintenance requirements; some models demand more upkeep than others. A balance of performance and practicality will serve you best as you make this critical decision.

Maintenance and Upkeep of the Best Heat Recovery Ventilator

Regular maintenance is essential for the best heat recovery ventilator to function properly. Without it, efficiency can dip significantly over time. Start by inspecting the unit for any signs of wear or damage. Pay close attention to seals and gaskets; these components often deteriorate and may need replacement.

Cleaning is another crucial step. Dust, dirt, and other debris can accumulate in the exchanger plates or coils, hindering performance. Regularly scheduled cleanings help maintain airflow and effectiveness. Monitoring operational parameters also plays a vital role. Watch temperature differentials and flow rates; significant changes could indicate underlying issues that require immediate attention.

Remember lubrication! Components such as fans or motors need proper lubrication to run smoothly without excessive strain. Documenting maintenance activities helps track patterns over time, ensuring you address potential problems before they escalate into costly repairs.

Potential Impact on Energy Efficiency with Passive Ventilation with Heat Recovery

The future of passive ventilation with heat recovery is promising. Technological innovations are set to enhance its efficiency and applicability across various sectors. For instance, advancements in materials science could lead to lighter, more efficient designs that maximize energy recovery potential.

Innovative technologies are also on the rise. The integration of IoT devices allows for real-time monitoring and adjustments, optimizing performance based on current conditions. This adaptability could significantly reduce energy consumption in both residential and industrial settings.

As industries increasingly focus on sustainability, heat-recovery exchangers will be crucial in meeting environmental goals. By recovering wasted heat, businesses can lower their carbon footprint while reaping financial benefits.

Moreover, policy changes aimed at promoting green technologies may further accelerate the adoption of these systems. Incentives for implementing energy-efficient solutions can encourage companies to invest in heat-recovery technology.

With continued research and development, we can expect even greater strides toward maximizing energy efficiency through heat-recovery exchangers over the coming years. The impact these advancements will have on overall energy consumption could be profound, transforming not just individual facilities but entire industries toward a more sustainable future.

Conclusion

Heat recovery exchangers are valuable for maximizing energy efficiency in various industries and applications. By recovering waste heat and utilising it in other processes, they can significantly reduce energy consumption, lower operating costs, and decrease carbon emissions. Furthermore, regular maintenance and proper installation are crucial for ensuring optimal performance and longevity of heat-recovery exchangers. It is recommended to consult with a professional engineer or supplier before making any decisions regarding heat-recovery systems.

FAQs:

Q: Can I install a heat recovery exchanger in my existing system?

A: Yes, depending on your system’s type, you may have options for retrofitting a heat recovery exchanger. Consult an expert to determine the feasibility of installing one in your current system.

Q: How much can I save on my energy bills using a heat-recovery exchanger?

A: The amount saved will vary depending on factors such as your industry, the size of your facility/system, and the type of heat-recovery exchanger used. However, studies have shown that implementing a well-designed heat recovery system can result in significant savings ranging from 10% to 50%.

Q: Are there any potential drawbacks or limitations when using a heat-recovery exchanger?

A: While there are numerous benefits to using a heat recovery system, it is essential to carefully consider potential limitations specific to your application. These may include space constraints for installation or compatibility issues with particular processes or equipment.

| Related Business Listings |

| Contact Directory |

| Local Business Profiles |