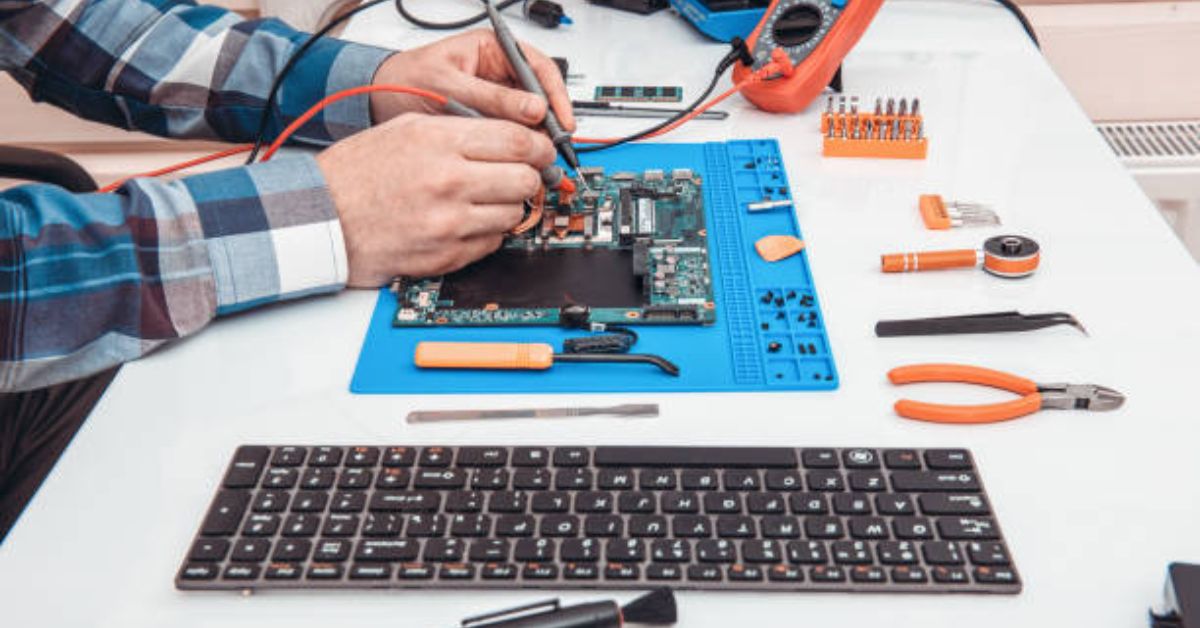

Printed Circuit Boards (PCBs) are essential for many electronic devices, like smartphones and medical equipment. The performance and reliability of these devices largely depend on the quality of their PCB design and layout. This is where professional PCB layout services come in. These services make sure that PCBs are designed, laid out, and manufactured to meet high standards of quality and functionality.

In this article, we’ll explore what professional PCB layout services entail, why they are essential, and how they can benefit manufacturers and engineers. By the end, you’ll have a clear understanding of how these services enhance PCB design, ensuring that your electronic products meet industry standards and perform optimally.

1. What Are PCB Layout Services?

PCB layout services encompass the process of arranging the various components, traces, and layers of a printed circuit board to achieve optimal performance, efficiency, and manufacturability. Layout services are typically the final stage in the PCB design process, where an initial concept is translated into a functional and manufacturable PCB.

A professional PCB layout service provider considers several critical factors, such as signal integrity, power distribution, thermal management, and component placement. This process requires specialized software tools and expertise to ensure that the design is effective and complies with industry standards.

2. The Importance of Professional PCB Layout Services

The success of an electronic product relies significantly on a well-designed PCB layout. Poor layout choices can result in malfunctioning devices, reduced lifespan, or costly redesigns. Professional PCB layout services are vital for ensuring that PCBs are designed to maximize performance and minimize errors. Here are some reasons why these services are essential:

Improved Signal Integrity: High-quality layout services minimize electrical interference, cross-talk, and noise, ensuring that the device operates smoothly.

Enhanced Thermal Management: Effective PCB layout helps dissipate heat, preventing components from overheating and prolonging the life of the device.

Efficient Power Distribution: Properly designed layouts ensure that power is distributed evenly across the board, avoiding voltage drops or hotspots.

Reduced Manufacturing Costs: A well-thought-out layout reduces the likelihood of errors during production, leading to lower manufacturing costs and fewer waste materials.

3. Key Steps in the PCB Layout Process

Professional PCB layout services follow a structured process to deliver a design that meets both the client’s requirements and industry standards.

a) Initial Design Review and Requirements Gathering

First, review the project requirements carefully. Understand how the device will work, the conditions it will face, and the specific needs for signal quality, energy use, and heat management. During this stage, layout designers will discuss the details with engineers and clients to gather all the necessary information.

b) Schematic Capture

The schematic is the blueprint of the PCB, detailing the connections between components. Designers use schematic capture software to create an initial design layout, providing a clear representation of how the circuit should function. This step lays the foundation for the physical layout process.

c) Component Placement

The next step involves placing components on the board. Professional layout services prioritize the placement of high-speed components, connectors, and power modules, optimizing their position to enhance performance and minimize noise. Component placement also considers spacing and clearances to ensure manufacturability.

d) Routing and Trace Layout

Routing is the process of creating the electrical connections between components on the PCB. Professional PCB layout services focus on creating optimized traces, which involves selecting the appropriate width and spacing of traces to support the current flow and reduce signal loss. This step is crucial for maintaining signal integrity and ensuring efficient power distribution.

e) Layer Stack-Up

For complex PCBs, multiple layers are often required to accommodate power and ground planes, signals, and component connections. Professional layout services decide on the ideal layer stack-up for the design, considering factors like signal shielding, thermal management, and EMI (Electromagnetic Interference) reduction. Proper stack-up design is essential for minimizing interference and ensuring robust signal transmission.

f) Design Rule Check (DRC) and Electrical Rule Check (ERC)

Before finalizing the layout, a Design Rule Check (DRC) and Electrical Rule Check (ERC) are performed. These checks verify that the PCB meets all design rules and regulatory standards, such as minimum trace width, spacing, and clearance requirements. This step helps find and fix any problems early, which makes the manufacturing process go smoothly.

g) Final Review and Testing

A final review is conducted to ensure that the PCB layout meets all specified requirements. This stage often involves simulations and testing to validate the design’s performance under different conditions. By simulating the board’s behavior, layout professionals can detect and resolve any potential issues, such as signal interference or thermal buildup, before manufacturing begins.

4. Benefits of Professional PCB Layout Services

Working with a professional PCB layout service provider offers several advantages, particularly for companies developing complex electronic products. Here are some key benefits:

a) Optimized Performance and Reliability

Professional PCB layout services optimize the performance and reliability of the final product. By carefully considering factors such as signal integrity, thermal management, and power distribution, layout experts ensure that the PCB operates at its best.

b) Faster Time-to-Market

Experienced PCB layout service providers help make the design process smoother. They ensure the layout is completed quickly and accurately. This can save time when moving from design to production, allowing companies to get their products to market faster.

c) Reduced Production Costs

A well-designed PCB layout minimizes the risk of manufacturing errors, reducing the need for rework and ensuring a smoother production process. This leads to cost savings, both in terms of materials and production time.

d) Compliance with Industry Standards

Professional layout services are familiar with industry standards and regulations. By working with experts, companies can ensure that their PCB designs meet necessary compliance requirements, avoiding potential legal issues and improving the product’s marketability.

e) Support for Complex Designs

As devices become more complex, so do their PCB requirements. Professional layout services have the expertise and tools to handle intricate designs, including multi-layer boards, flexible PCBs, and high-frequency circuits.

5. Choosing the Right PCB Layout Service Provider

Selecting the right PCB layout service provider is essential for achieving a high-quality design. Here are some factors to consider when choosing a provider:

Experience and Expertise: Look for providers with experience in your specific industry and a track record of successful projects.

Software and Tools: Ensure that the provider uses advanced layout software, such as Altium Designer, OrCAD, or Allegro, to create accurate and optimized layouts.

Quality Assurance: Choose a provider that performs thorough testing and quality checks, including DRC and ERC, to ensure the layout meets all requirements.

Communication and Support: Effective communication is crucial during the design process. Select a provider that is responsive and willing to collaborate closely with your team.

6. Future Trends in PCB Layout Services

As technology evolves, so do the requirements and trends in PCB layout services. Here are some emerging trends to watch:

a) Miniaturization and High-Density PCBs

Devices are becoming smaller and more powerful, driving the demand for high-density PCBs. Professional layout services are adapting to this trend by developing layouts that fit more functionality into smaller spaces.

b) Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs are increasingly popular for wearable devices, automotive applications, and other products that require unique form factors. PCB layout service providers are gaining expertise in these layouts to meet growing demand.

c) Integration of AI in PCB Design

Artificial Intelligence (AI) is making its way into PCB design services, helping to automate the layout process and optimize designs for performance and manufacturability. AI tools can quickly identify potential issues, suggest improvements, and speed up the overall design process.

d) Enhanced Thermal Management Solutions

With more powerful devices generating more heat, thermal management is a growing concern. PCB layout services are implementing advanced techniques, such as thermal vias and heat sinks, to ensure that devices operate within safe temperature ranges.

e) Emphasis on Sustainability

As environmental concerns grow, there’s an increasing focus on sustainable PCB design. Many layout services are incorporating eco-friendly practices, such as selecting recyclable materials and optimizing designs for energy efficiency.

7. Conclusion

Professional PCB layout services are important in the electronics industry. They make sure printed circuit boards (PCBs) are designed for high performance, reliability, and easy manufacturing. These services help companies enhance their products, reduce costs, and speed up their time to market. By understanding the layout process and its benefits, manufacturers can make better decisions and find the right service provider for their needs.

If you are making simple electronics or complex industrial devices, working with a professional PCB layout service provider is very helpful. This choice ensures that your products meet industry standards and helps you create items that fit today’s technology-focused market.